Products

Browse our core categories. For specifications, datasheets or alternatives, request a quote.

Our valve portfolio covers the full envelope of pressure control and automation required in modern compressed air and process gas systems. We source precision‑machined bodies and high‑cycle internals that deliver consistent set points, tight shut‑off and long service intervals. From minimum pressure and combination valves that stabilise systems at start-up, to responsive solenoid and air‑operated units for automated lines, every product is specified for reliability, easy maintenance and compatibility with common standards. Safety and pressure relief valves are available in a range of materials, end connections and certifications to help you meet plant compliance without compromise.

- Minimum Pressure Valves

- Combination Valves

- Air & Solenoid Valves

- Pressure Relief Valves

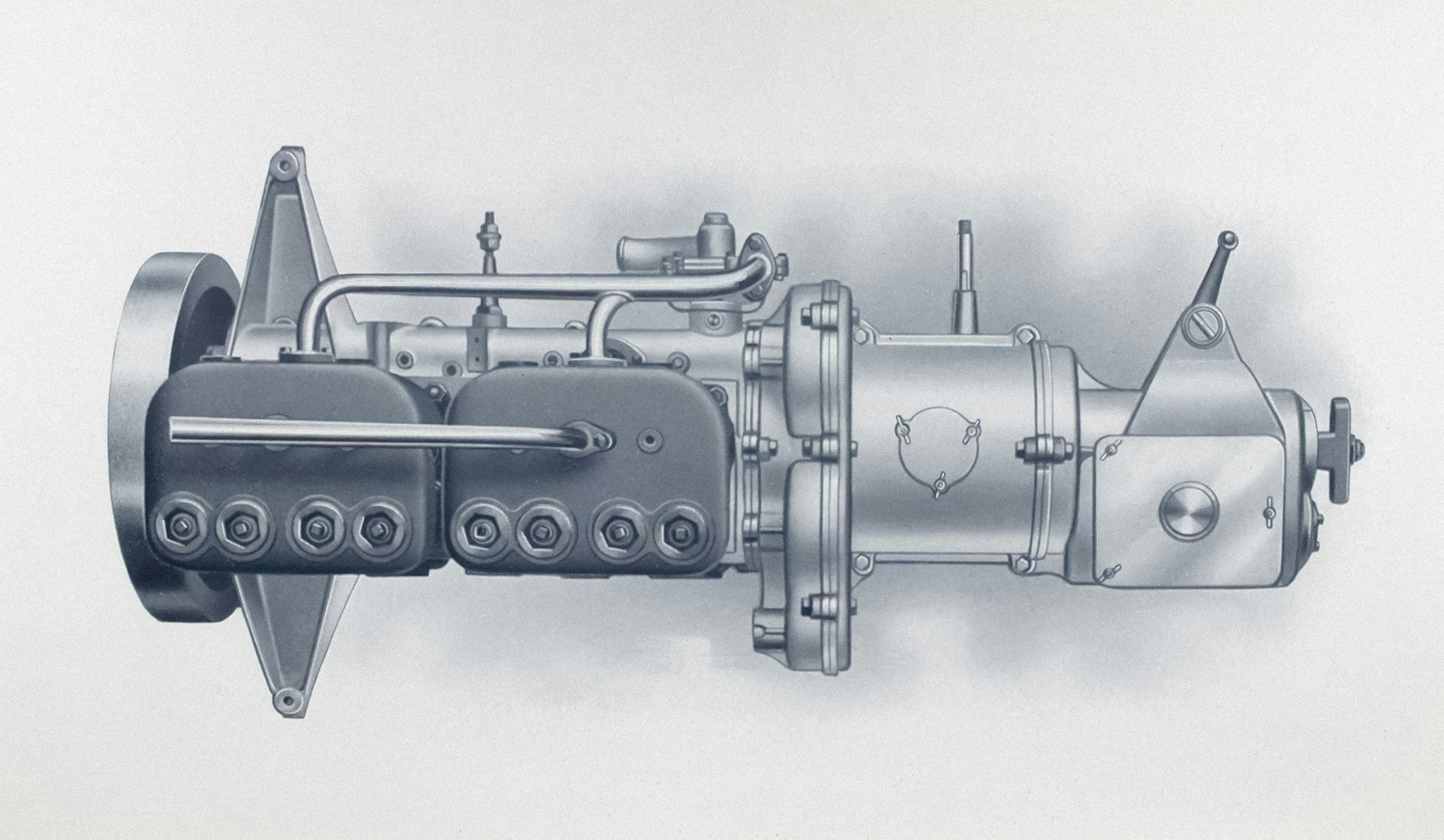

We supply the core components that determine a compressor’s efficiency and uptime. OEM‑grade screw blocks maximise volumetric efficiency and reduce energy use; matched safety valves protect vessels and downstream equipment; advanced synthetic lubricants maintain film strength at elevated temperatures and extend drain intervals. We also stock couplings, seals and alignment sets to restore performance after overhauls, along with complete service kits tailored to the most common rotary screw and piston platforms. Our aim is simple: shorten maintenance windows and keep your installed base running at design performance for longer.

- Screw Blocks

- Safety Valves

- Lubricants

- Couplings & Seals

- Service Kits

Clean, dry air and gas protects tooling, instrumentation and final product quality. Our filtration and separation media range provides multi‑stage protection from bulk liquids to sub‑micron aerosols and vapours. Activated alumina beads deliver dependable adsorption capacity for drying, while molecular sieves (3A, 4A, 13X) target specific contaminants and dew‑point requirements in gas separation duties. Coalescing and particulate inline filters safeguard distribution networks and equipment, and our oil‑water separators enable compliant condensate handling. Replaceable elements and cartridges are stocked to give you predictable lifecycle costs and fast turnaround on routine service.

- Activated Alumina

- Molecular Sieves (3A, 4A, 13X)

- Oil-Water Separators

- Inline Filters & Cartridges

Conditioning and storage equipment is the backbone of a stable compressed air plant. We supply receiver tanks sized for buffer capacity and pressure stability, as well as refrigerated and desiccant dryer technologies to hit your target dew point with minimal pressure drop. Heatless regenerative systems are available for critical environments requiring ultra‑low moisture content. High‑efficiency inline filters can be paired to meet ISO air quality classes. Every unit is selected with service access and energy efficiency in mind so you achieve dependable air quality at the lowest total cost of ownership.

- Air Receiver Tanks

- Refrigerated Air Dryers

- Desiccant & Heatless Regenerative Dryers

- Inline Filters

Accurate measurement underpins safe and optimised operation. Our instrumentation and controls catalogue includes pressure gauges for line and vessel monitoring, differential indicators for filter condition tracking, and flow meters to quantify air consumption and detect leaks. Temperature sensors help maintain safe compressor discharge and dryer operating windows. We also provide compact control panels and PLC‑ready solutions to integrate alarms, remote monitoring and automated sequencing, enabling visibility and smarter maintenance planning across your plant.

- Pressure Gauges

- Flow Meters

- Differential Pressure Indicators

- Temperature Sensors

- Control Panels

Distribution networks dictate overall system efficiency. We offer aluminium and stainless‑steel piping systems with smooth bores and corrosion resistance to minimise pressure drop and improve air quality. Quick‑connect fittings speed installation and allow easy modifications, while flexible hoses absorb vibration at equipment interfaces. Manifolds and headers simplify branch take‑offs, and expansion joints accommodate thermal movement for long‑term leak‑free performance. Our team can assist with sizing and layout guidelines to help you build an efficient, scalable network.

- Aluminium & Stainless Piping

- Quick Connect Fittings

- Flexible Hoses

- Manifolds & Headers

- Expansion Joints

Planned maintenance is the cheapest maintenance. Our spare parts and kits combine the consumables required for routine service—seals, gaskets, O‑rings, bearings and filter elements—so technicians have everything to hand. Overhaul kits are available for major intervals on popular compressors, reducing downtime and procurement friction. We keep fast‑moving spares on the shelf for urgent repairs and can source hard‑to‑find items through our partner network, helping you return equipment to service quickly and confidently.

- Gaskets & O-Rings

- Replacement Filters & Elements

- Bearing Kits

- Overhaul Kits

- Fast-Moving Spares

A safe plant is a productive plant. We supply safety and ancillary equipment that protects people, equipment and compliance status. Certified safety valves and burst discs provide overpressure relief across vessels and process lines. Automatic and manual drain valves remove condensate before it causes corrosion and pressure loss. Acoustic silencers reduce exhaust noise, while vibration mounts limit transmitted loads to structures. Protective enclosures are available for harsh or outdoor locations, extending equipment life and simplifying maintenance access.

- Safety Valves & Burst Discs

- Automatic & Manual Drain Valves

- Noise Reduction Silencers

- Vibration Mounts

- Protective Enclosures